Wafer foundry enters the 2.0 era

From a technical perspective, the 3nm process accounted for 15% of TSMC's wafer sales in the second quarter, while 5nm and 7nm accounted for 35% and 17%, respectively. The 7nm process accounts for 17%. Overall, advanced technologies (7nm and below) accounted for 67% of TSMC's overall wafer revenue in the second quarter of 2024.

According to TSMC's publicly released financial report, advanced processes such as 3nm and 5nm have shown extremely strong development momentum driven by the AI wave. The 3nm process has been increasing in volume since the third quarter of last year, with revenue accounting for 15% in the second quarter of this year, up from 6% in 2023. And 5nm's revenue proportion increased from 20% in the first quarter of 2022 to 35% in the second quarter of this year. However, the overall revenue proportion of mature processes and special processes has shrunk since then.

At present, the application scenarios of 3nm technology are mainly high-end mobile phones. Industry insiders have revealed that in the second half of this year, TSMC's monthly production of 3nm chips will increase from the current 100000 to 125000 to meet the needs of major customers such as Apple, Intel, Qualcomm, and MediaTek. According to sources from semiconductor equipment companies, TSMC's production capacity for 5nm and 3nm processes is already at full capacity, especially with 3nm production capacity being in short supply. TSMC's current 5/3nm process capacity utilization rate has reached 100%.

TSMC stated that the demand for 3nm processes is very strong and does not rule out the possibility of converting more 5nm processes to 3nm. It is reported that the tool versatility between the N5 and N3 processes is more than 90%, and these two nodes are located in Tainan, Taiwan, China, China. The wafer factory is close to each other, so the conversion is easier. Additionally, it is worth noting that ASML, the global leader in lithography, also pointed out at the press conference the previous day that the third-generation EUV lithography machine Twinscan NXE: 3800E system, mainly used for semiconductor chips with 3nm and 2nm processes, will be delivered in large quantities in the second half of the year. It is reported that TSMC holds the majority of orders in this regard.

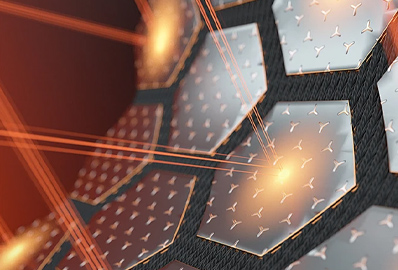

According to official sources, TSMC's 3nm process node symbolizes the last generation of FinFET based manufacturing technology, and the next generation of 2nm chips will adopt full gate (GAA) nm chip transistor technology. TSMC claims that GAA transistors improve their current control capability by surrounding the gate around the channel, significantly enhancing PPA characteristics. Compared to N3E, N2 can reduce power consumption by 25% -30%, improve performance by 10% -15%, and increase transistor density by 15%.

At present, TSMC's 3nm process family mainly includes four versions, namely the basic N3, cost optimized N3E, performance enhanced N3P, and high-voltage tolerant N3X. Among them, N3E and N3P are both optical reduced versions based on N3, which can reduce complexity and cost while improving performance and transistor density. N3X is a process specifically designed for the HPC field, which can support higher voltages and frequencies, thereby achieving stronger computing power.

Although TSMC's 2nm has not yet made a profit, TSMC has revealed that customers have a high interest and participation in 2nm, which also represents that TSMC will continue to reap the dividends in the new round of industry trends. It is reported that TSMC's N2 process will enter the trial production stage in the third quarter of this year and enter mass production in the fourth quarter of 2025. TSMC stated that it expects N2 to have a higher number of new projects in the first two years compared to N3 and N5 during the same period, with a similar expansion speed to N3 and a faster revenue contribution and gross profit margin ramp up than N3. The performance enhanced N2P and voltage enhanced N2X will also be launched in 2026, and almost all AI chip companies are interested.

The more long-term advanced process node is A16 (1.6nm) after 2027. It is reported that TSMC's A16 will become the first "angstrom level" process node, introducing backside power supply network technology (BSPDN) for the first time, and combining with GAAFETnm chip transistors, marking a new era in semiconductor manufacturing.

HPC hgh-performance computing has become a stable core of TSMC's performance

At present, HPC high-performance computing has replaced mobile phone business as the core supporting TSMC's performance growth. In the second quarter, HPC high-performance computing order revenue accounted for more than half of 52%, a month on month increase of 6%, while the proportion of smartphone business revenue decreased by 5% to 33%. In addition, revenue from IoT platforms, automotive, DCE digital consumer electronics, and other fields accounted for 6%, 5%, 2%, and 2% of TSMC's total revenue, respectively.

From the perspective of business growth momentum, DCE's digital consumer electronics business revenue increased by 20% month on month, demonstrating strong growth momentum. It is reported that this business includes T-Con, PMIC, WiFi chips, etc., mainly targeting application scenarios such as set-top boxes and smart TVs. Industry insiders have stated that AI enabled smart devices have been mentioned in TSMC's DCE business, and it is speculated that this part may be related to AI business. In addition, the smartphone business still did not show a significant rebound in the second quarter, with revenue decreasing by 1% month on month.

The copyright of the articles on this website belongs to the original author. The content is the author's personal opinion. This website only provides reference and does not constitute any investment or application advice

The purpose of reposting this article is to convey more information, and does not mean that this website agrees with its views or takes responsibility for its authenticity. If there are any issues related to the content, copyright, or other aspects of the work, please contact our website within 30 days, and we will delete the content as soon as possible